Sustainable refrigeration for the poultry sector: efficiency, safety, and decarbonization

In the poultry sector, the adoption of sustainable refrigeration systems enhanced with natural fluids and digital controls can reduce consumption and emissions, ensuring safety and quality.

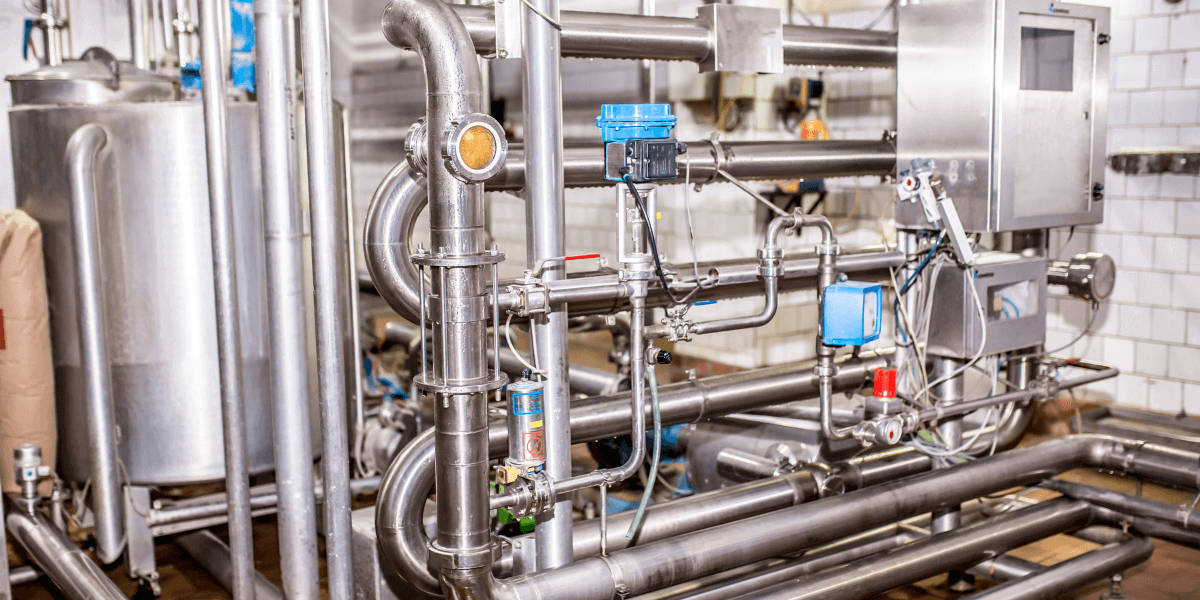

In the poultry sector , product preservation and handling require reliable, high-performance refrigeration systems . However, with regulatory pressures on refrigerant gases and the imperative of sustainability, the need for more efficient and less impactful solutions is growing. Some companies are already experimenting with systems using natural fluids, digital controls, and energy optimization to reduce consumption and emissions. The goal is to ensure optimal hygiene and sanitation conditions while minimizing energy consumption and carbon footprint, leveraging heat recovery technologies, cogeneration, or modular systems.

The specific needs of poultry refrigeration

In poultry farming , slaughterhouses, and logistics, refrigeration plays a key role not only in preserving meat and processed meat, but also in controlling quality, preventing microbial growth , and maintaining the cold chain during storage and transportation. Temperature fluctuations must be minimal, the system's capacity must be proportional to variable product loads, and humidity control is essential to avoid unwanted condensation in the rooms.

These requirements require continuous operation, modular solutions, and redundancy to ensure reliability even under extreme conditions.

Technological strategies to make it sustainable

The most promising solutions include the adoption of low-impact natural refrigerants (ammonia, CO₂, hydrocarbons where permitted), low-charge systems , indirect circuits with secondary fluid, high-efficiency compressors, and heat recovery.

By integrating these with modern control systems (IoT, predictive algorithms), it's possible to optimize operations at any time of day. In some poultry facilities, refrigeration modules are combined with solar thermal panels for water preheating or air conditioning, maximizing the use of renewable energy sources.

Innovate to reduce costs and impacts

Adopting sustainable solutions can result in significant reductions in electricity consumption of up to 20-30%, lower operating costs, and a faster return on investment when the system is properly sized. On an environmental level, migrating from synthetic refrigerants to natural alternatives reduces direct and indirect emissions. Furthermore, efficient systems are more resilient to price fluctuations. For poultry farms operating on tight margins, these solutions can become a competitive advantage in the market, especially when accompanied by environmental certifications.

What is holding back the adoption of natural solutions?

There is no shortage of obstacles:

-

the initial investment can be high, especially for replacements of older systems;

-

local availability of natural refrigerants may be limited;

-

local legislation

-

and permits for high volumes of ammonia may be more restrictive.

Training technical personnel to manage natural systems and perform specialized maintenance is essential. Furthermore, each system must be designed with attention to actual load and peak demand to avoid waste or inefficiencies.