Rigid or flexible wires in refrigeration systems: which to choose?

In refrigeration systems, the choice between rigid and flexible cables affects the safety, efficiency and longevity of the system.

In the professional refrigeration sector, choosing the right electrical cable is a highly important technical aspect, often crucial to the safety, reliability, and longevity of the systems.

During design, installation, or maintenance, operators often find themselves faced with the choice between rigid (solid) and flexible (multi-strand) cables . The difference is not only related to the conductor structure, but directly affects factors such as vibration resistance , ease of installation, current conductivity , and response to mechanical stress—critical characteristics in complex environments such as those found in refrigeration systems.

Construction differences and application advantages

Rigid cable is composed of a single metal conductor, while flexible cable is made of numerous thin strands twisted together. This difference in construction translates into different performance levels depending on the type of system:

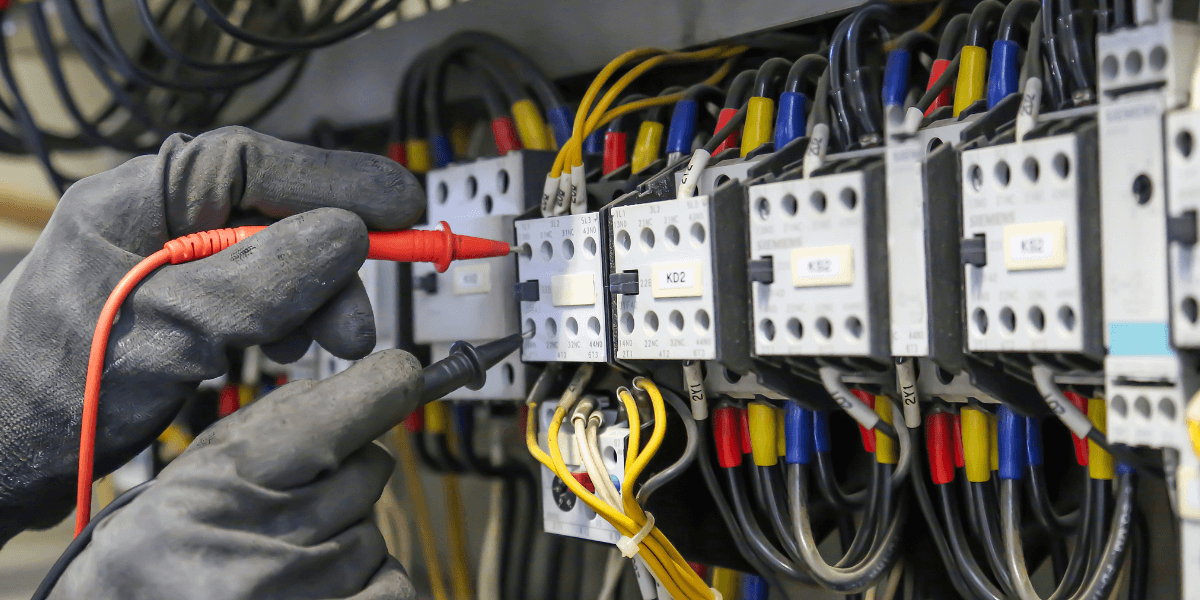

- Rigidity and stability: The rigid conductor is less flexible, but more stable and easier to attach in stationary connections. It is ideal for main power lines or electrical panels where mechanical stress is not expected.

- Flexibility and vibration resistance: Flexible conductors, thanks to their multi-strand structure, better withstand the movements and vibrations generated by compressors, fans, and heat pumps, typical of refrigeration systems. They are particularly suitable for areas subject to temperature fluctuations or variations.

- Ease of installation: in complex routes, inside ducts or electrical cabinets, the flexible cable allows for easier and quicker installation, easily adapting to curves and corners without compromising performance.

These differences highlight how the choice of conductor type must be calibrated based on the system configuration and the operating conditions in which the refrigeration system will work.

Electrical performance and good installation practices

Electrically , solid wires generally offer lower electrical resistance and better conductivity over long runs, which is why they are preferred for main connections and power lines.

Flexible cables , on the other hand, guarantee greater mechanical resistance and better adaptability during assembly or maintenance operations, proving more practical in internal connections and in components subjected to continuous vibrations.

To ensure maximum efficiency, it is good practice to:

- use crimp terminals or ferrules to ensure stable and secure connections;

- avoid excessive bending of the conductor , which can reduce the life of the cable;

- Always check the compatibility between the cable cross-section and the nominal current foreseen by the project.

Correct cable selection and installation plays a key role in maintaining the system's energy performance, preventing overheating, dispersion, and failures due to vibrations or loose connections.

Informed choice for efficient and safe systems

From the perspective of European HVAC/R system design, the distinction between rigid and flexible cables is not only technical, but also strategic: choosing the most suitable type of conductor ensures operational continuity, electrical safety, and reduced system downtime.

For this reason, designers and installers must carefully evaluate the operating environment, expected vibrations, and maintenance frequency, integrating cable selection into the overall system design.

Correct wiring selection represents an investment in the longevity and efficiency of the refrigeration system, as well as in the safety of the technical personnel who manage its maintenance.