Ammonia trigeneration: cooling, heating, and energy in a single sustainable solution

Ammonia trigeneration integrates cold, heat and electricity in a single highly efficient system, with zero GWP and ideal applications in the industrial refrigeration sector.

Trigeneration represents one of the most advanced technologies for energy efficiency in the HVAC-R sector: it allows the simultaneous production of heat, cold and electricity from a single primary source .

When integrated with ammonia (NH₃) as a natural refrigerant, trigeneration combines high thermodynamic efficiency, no GWP and reduced greenhouse gas emissions .

From a single energy source – which can be biomass, cogeneration, solar thermal, or other local thermal resource – it is possible to meet, in a coordinated manner, the heating, cooling, and power needs of industrial processes or complex infrastructures.

A system designed to respond efficiently to the variable loads typical of professional and industrial refrigeration .

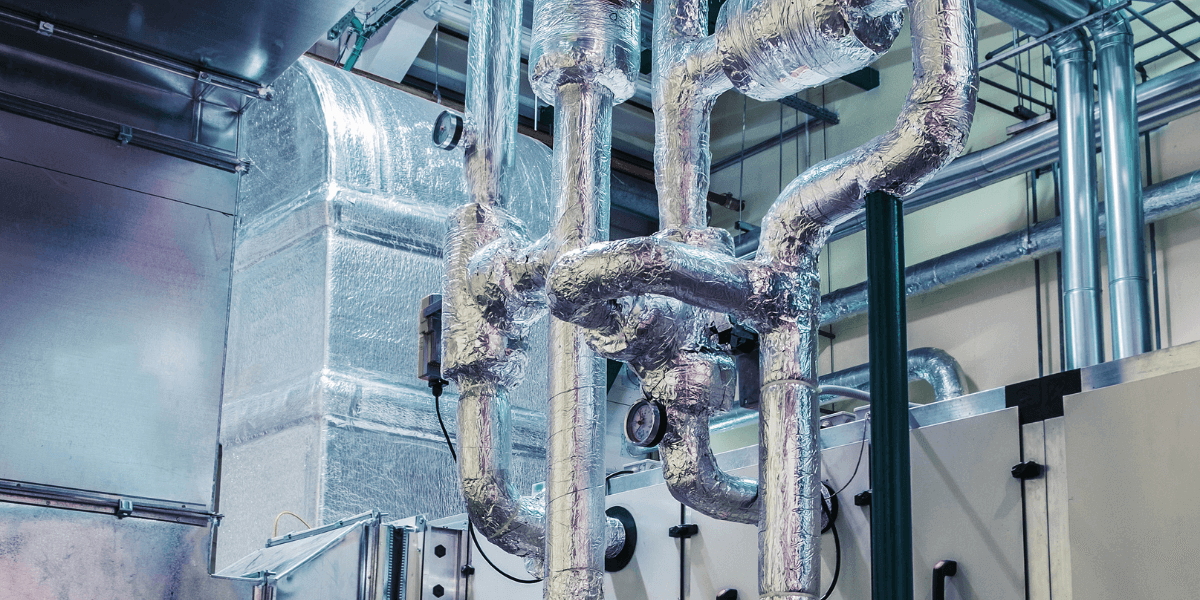

How an ammonia trigeneration plant works

The principle is that of extended cogeneration : a primary source generates thermal and electrical energy.

Part of the heat is then used to power an ammonia refrigeration cycle , capable of producing cold for air conditioning or industrial processes.

Thanks to its high latent heat of evaporation, ammonia is able to offer high performance in refrigeration cycles, minimizing energy consumption.

The entire system is managed by advanced digital controls, which modulate the three modules – electrical, thermal, and refrigeration – based on actual demand, ensuring maximum efficiency and operational continuity.

Furthermore, waste heat recovery allows for further improvements in energy balance, limiting waste and increasing the overall sustainability of the system.

Advantages for efficiency and sustainability

The benefits of ammonia trigeneration are expressed on several levels:

- Higher overall energy efficiency than separate systems;

- Reduction of fossil fuel consumption and CO₂ emissions ;

- Adoption of a natural refrigerant with zero GWP and zero ODP ;

- Greater energy independence for production sites with continuous heating and cooling needs.

For the industrial refrigeration sector, this technology allows for lower operating costs, improved thermal stability, and an enhancement of the company's environmental image.

A concrete step towards truly sustainable refrigeration, without compromising on performance.

Design challenges and safety requirements

Integrating ammonia trigeneration requires careful planning and specialized expertise.

Thermal, refrigeration, and electrical modules must be sized in a balanced way, to avoid one cycle prevailing over the others and compromising overall efficiency.

Ammonia, although a natural and high-performance refrigerant, entails specific safety requirements:

- leak containment and detection systems;

- forced ventilation and emergency procedures;

- compliance with EN 378 and ATEX regulations , as well as local provisions regarding risky systems.

The initial investment remains higher than conventional systems, but the long-term economic and environmental benefits justify their adoption in the most energy-intensive contexts.

Ideal applications in the industrial and refrigeration sectors

Ammonia trigeneration finds application in industrial sectors with high thermal and refrigeration consumption , such as:

- food and dairy industry;

- cold storage logistics hubs and cold storage warehouses;

- chemical or pharmaceutical process plants;

- hospitals, shopping centers and large buildings with constant energy loads.

Particularly effective in contexts where a local heat source is available (biomass, waste heat, solar thermal), this technology allows every kWh produced to be exploited, maximizing the energy and economic return of the system.