Sustainable industrial refrigeration: natural refrigerants and new efficiency standards

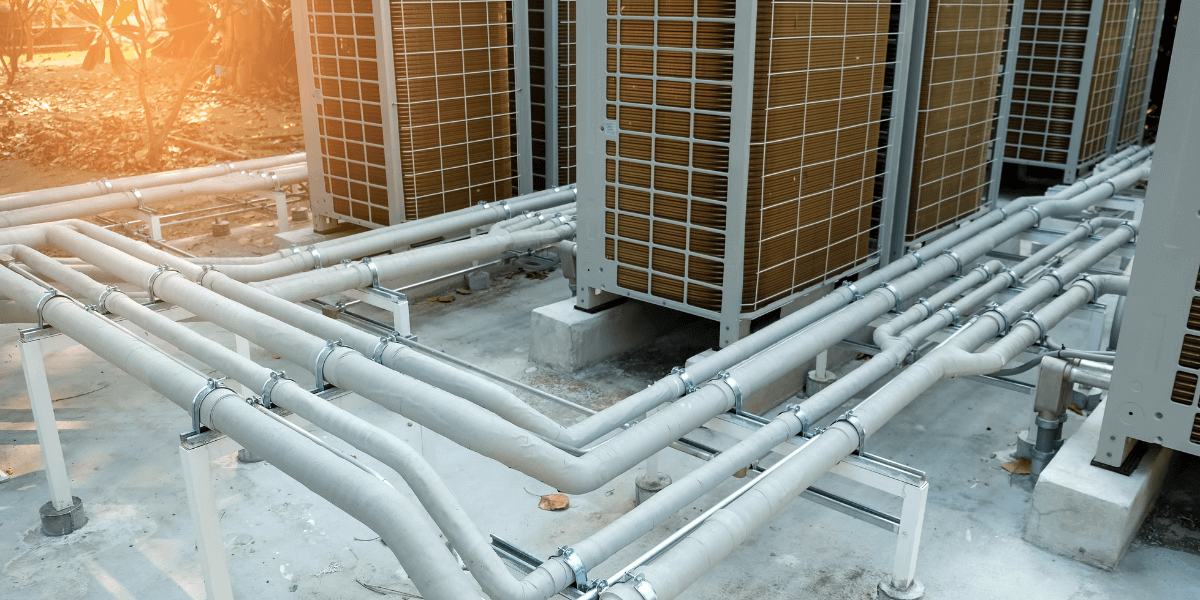

Sustainable industrial refrigeration integrates natural refrigerants and high-efficiency solutions to reduce consumption, emissions, and regulatory risks while maintaining high operational performance.

In the industrial refrigeration sector, sustainability is no longer an afterthought, but a structural variable that impacts design, operating costs, and business competitiveness. Regulatory changes , combined with the need to reduce consumption and emissions , are accelerating the transition from traditional systems to solutions based on natural refrigerants and high-efficiency systems.

A transition that affects the entire industrial refrigeration supply chain and requires increasingly specialized technical skills.

From traditional refrigerants to natural fluids

Systems historically based on high-GWP synthetic refrigerants are gradually giving way to technologies that use ammonia (NH₃), CO₂ , and hydrocarbons , fluids with zero or very low environmental impact. This evolution responds not only to regulatory requirements, but also to a broader industrial logic, aimed at reducing energy consumption and maintaining cost stability over time.

The adoption of natural refrigerants improves the thermodynamic efficiency of plants, reduces the risk of future regulatory restrictions, and strengthens the overall sustainability of production processes, maintaining high levels of operational reliability.

Efficiency, reliability and sustainability: a design balance

Sustainable industrial refrigeration is based on a design approach that integrates three key elements:

- energy efficiency , achieved through variable speed compressors, high-performance exchangers and advanced control systems;

- operational reliability , essential in industrial contexts where continuity of cold is critical;

- reduction of environmental impact , guaranteed by the use of natural refrigerants and by the reduction of electricity consumption and indirect emissions.

This balance allows for the creation of systems capable of combining high performance, safety, and environmental friendliness, transforming sustainability into a concrete factor of competitiveness.

Operational implications for the industrial cold chain

For designers, installers, and maintenance technicians, the transition to sustainable refrigeration requires a rethinking of their technical approach.

It's not about replacing a fluid, but about rethinking the entire system: from the compatibility of existing systems with natural refrigerants, to safety management, to maintenance planning and continuous performance monitoring.

A comprehensive cost analysis also becomes crucial, considering not only the initial investment but also the medium- to long-term benefits related to lower consumption, greater reliability, and reduced regulatory risks.

A transition already underway

Sustainable industrial refrigeration is no longer a theoretical goal, but an increasingly widespread operational reality. The integration of natural refrigerants and efficient technologies is redefining industry standards, demonstrating that it is possible to reduce environmental impact without compromising performance and safety.

For the industrial sector, this evolution represents one of the most concrete levers for addressing the ecological transition, strengthening the role of refrigeration as a strategic infrastructure for more efficient and responsible production processes.