A2L Refrigerants: The New Generation of Refrigeration: Technical Challenges and Market Opportunities

A2L refrigerants, with low GWP and low flammability, open a new era for refrigeration: efficiency, safety and sustainability require updated skills and innovation.

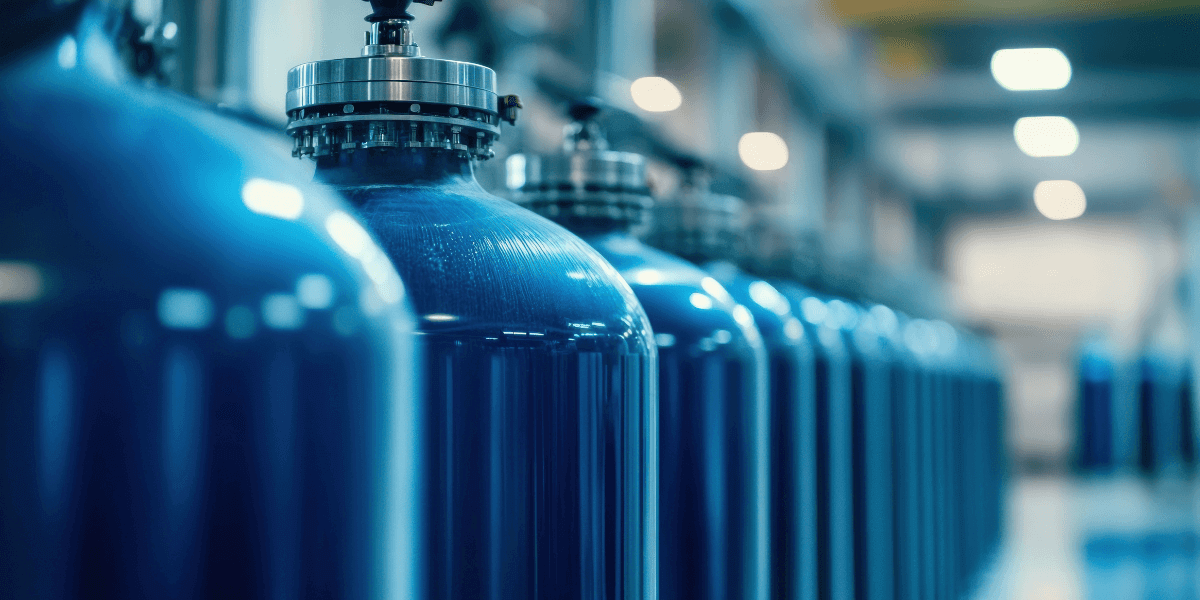

The refrigeration and air conditioning sector is undergoing a profound transformation, driven by the need to reduce environmental impact and comply with European regulations on fluorinated gases.

In this scenario, A2L refrigerants – characterised by low GWP (Global Warming Potential) and low flammability – are establishing themselves as the reference solution for new HVAC/R systems.

These gases, destined to progressively replace traditional refrigerants such as R-410A and R-134a , allow for a significant reduction in climate-altering emissions without sacrificing performance and reliability.

Their diffusion is also supported by the new F-Gas Regulation and the European decarbonisation objectives, which push towards an increasingly widespread use of low environmental impact fluids.

New skills and tools for a safe transition

The introduction of A2L refrigerants brings with it an evolution in the methods of installation, maintenance and management of systems.

To operate safely, professionals in the sector must use specific tools and certified components , such as:

- A2L compatible vacuum pumps and pressure gauges ;

- updated recovery units and leak detection systems;

- ventilation and active protection devices for closed environments.

At the same time, technical training becomes essential: refrigeration technicians must be updated on safety procedures, load sizing, and flammability risk management.

Only with in-depth knowledge of new fluids is it possible to guarantee compliant, high-performance and sustainable installations.

Managing the transition: operational challenges and supply chain adaptation

Like any technological change, the transition to A2L also presents operational challenges to address.

The availability of certified components, warehouse upgrades, and equipment upgrades are the main obstacles in the initial phase.

Furthermore, the coexistence of old and new refrigerants requires careful management of existing systems, which are often not compatible with the new fluids without targeted modifications.

Despite these challenges, the transition to A2L is a necessary and strategic step: it allows for improved energy efficiency, reduced environmental impact, and maintained competitiveness in an increasingly sustainability-oriented market.

An opportunity to innovate the refrigeration sector

Beyond the regulatory aspects, the spread of A2L refrigerants represents a great opportunity for the refrigeration supply chain.

Operators who anticipate change will be able to distinguish themselves as qualified partners, capable of offering up-to-date solutions, advanced maintenance, and targeted technical consultancy.

For manufacturers, installers, and designers, A2Ls are not just a regulatory requirement, but a lever for innovating refrigeration and air conditioning systems, building more efficient, safe, and environmentally friendly systems.

An evolution that consolidates the sector's transition towards sustainable, new-generation refrigeration .